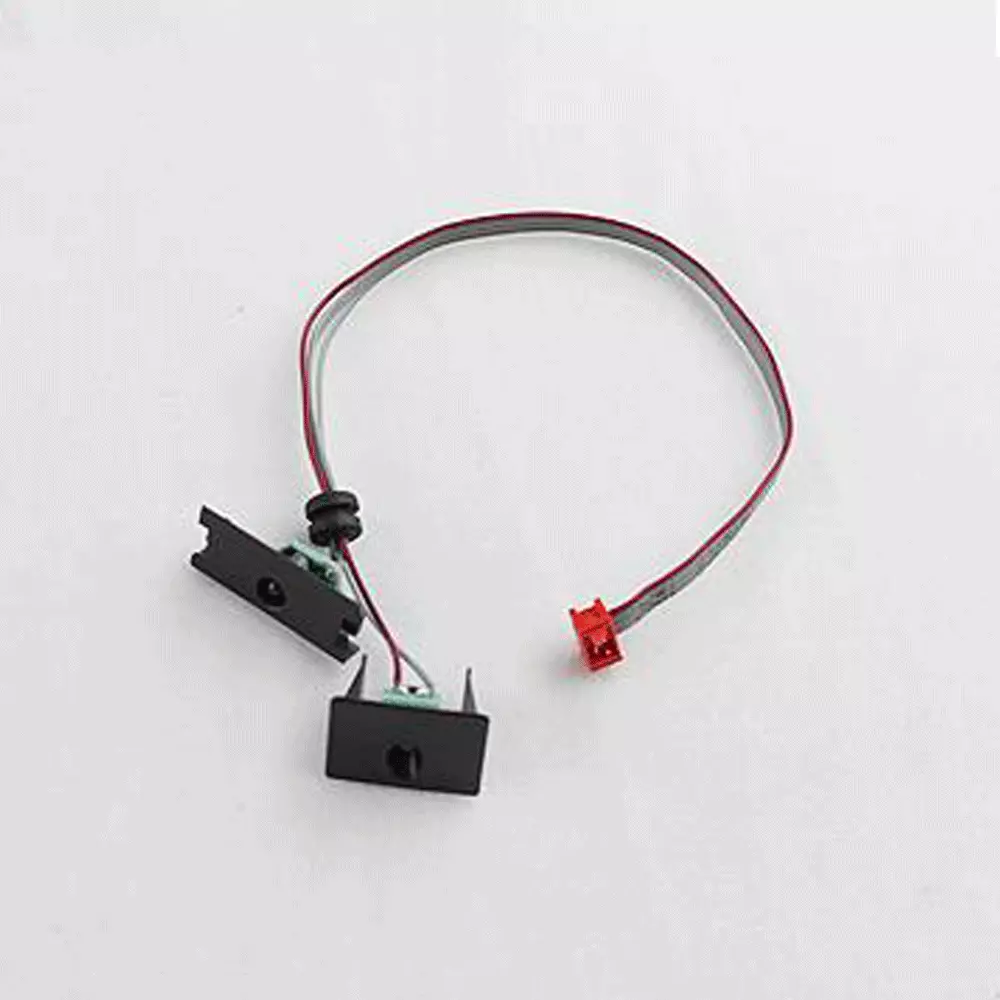

Industrial Equipment Connecting Wire

MOQ: 1 Pieces

Delivery time: 7 Day

Electrical performance adaptability: meets the multi-voltage/current requirements of industrial equipment (e.g. DC 24V-1000V, AC 110V-690V), supports high power transmission (hundreds of amperes), and has low resistance and high insulation resistance characteristics to ensure signal stability and efficient transmission of electrical energy.

Environmental tolerance: Adapt to the extreme conditions of industrial scenarios, including a wide temperature range of -50℃ to 150℃, oil/acid/alkali/moisture/ultraviolet resistance, and vibration- and shock-resistant mechanical stability, guaranteeing the long-term reliability of the equipment under complex working conditions.

Mechanical strength and flexibility: The use of high-strength insulating materials (e.g. cross-linked polyethylene, fluorine rubber) and tensile conductors, combined with a small bending radius design (e.g. ≤ 5 times the diameter of the wire), taking into account the durability and flexibility of the wiring, suitable for automated production lines, robots and other dynamic scenarios.

Safety and certification standards: Passing safety certifications such as flame retardant (UL VW-1/FT1) and fire resistant (IEC 60332), complying with environmental regulations (RoHS/REACH), and possessing electromagnetic compatibility (EMC) design to minimize signal interference between industrial equipment.

Customization and Scenario Adaptation: Provide multiple core counts (e.g. 2-100 cores), multiple wire diameters (0.1mm²-50mm²), and shielding layer (aluminum foil/braided mesh) to meet the needs of different industrial scenarios, such as automation control, sensor connection, and motor drive.

Product Details

Previous: No More